Modular Cleanrooms Are Taking Over: Here’s Why Your Industry Can’t Ignore Them

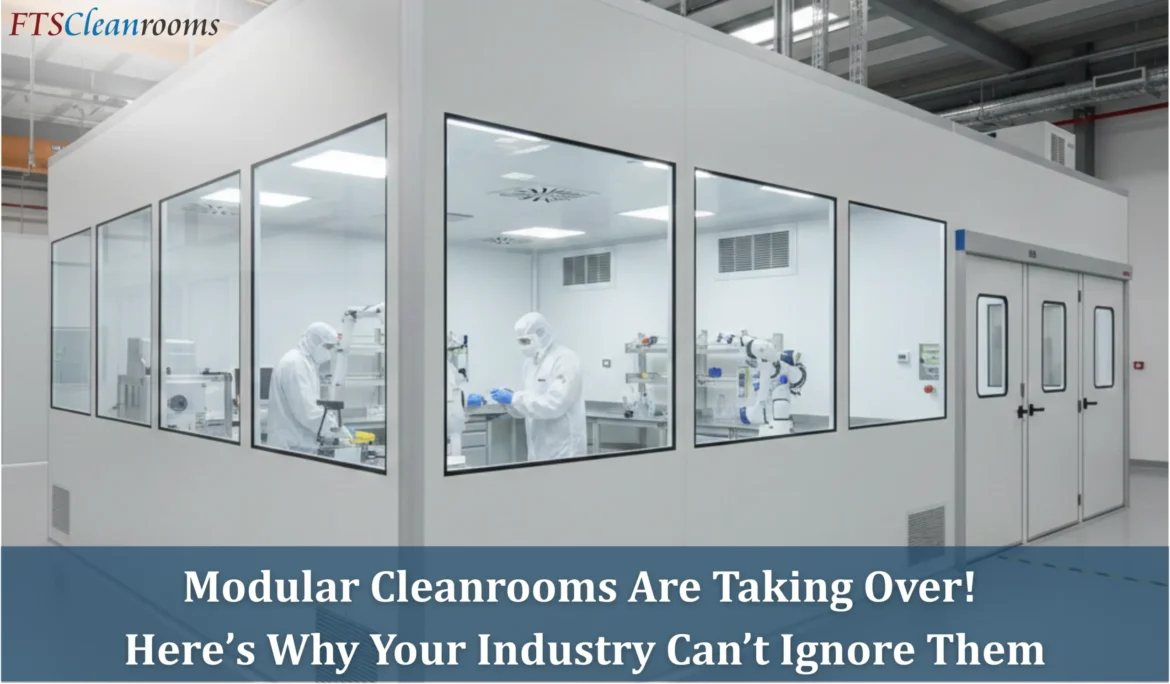

Imagine a world where cleanrooms, the ultra-controlled spaces essential for pharmaceuticals, biotech, electronics, and high-tech manufacturing, can be put together as easily as stacking building blocks. This is the era of modular cleanrooms, a revolution that’s changing the way industries operate worldwide.

Gone are the days when building a cleanroom meant months of planning, endless approvals, and soaring costs. Today, modular cleanrooms offer unmatched flexibility, fast deployment, and also cost efficiency. So businesses scale quickly, adapt to new industry standards, and innovate without limits. From pharmaceutical labs to advanced electronics facilities, modular cleanrooms are becoming the new standard for modern, forward-thinking industries. This blog will talk about the rise of modular cleanrooms and why every industry should adapt to the change if they don’t want to be left out.

What Are Modular Cleanrooms?

At their core, modular cleanrooms are prefabricated, highly controlled environments designed to maintain ultra-clean conditions for sensitive operations. Unlike traditional cleanrooms, which are built on-site from scratch, cleanroom modular systems are constructed off-site and assembled like a sophisticated puzzle. This approach not only accelerates the construction timeline but also ensures consistent quality and compliance with stringent regulatory standards.

The Driving Force Behind the Rise of Modular Cleanrooms

Several factors have fueled the rise of modular cleanrooms in recent years. Industries are evolving rapidly, requiring spaces that can adapt to changing production needs. The demand for flexible cleanroom solutions for modern industries has never been higher. Pharmaceutical companies, for example, face fluctuating production volumes, requiring scalable solutions that traditional cleanrooms cannot provide. Similarly, electronics manufacturers need spaces that can quickly accommodate new technologies without extensive downtime.

Key Benefits of Modular Cleanrooms

One of the biggest advantages of modular cleanrooms is their flexibility. Unlike traditional construction, which locks you into a fixed layout, flexible cleanroom solutions allow businesses to reconfigure their space as needed. This adaptability is critical in industries where processes evolve rapidly.

Cost-effectiveness is another major benefit. Cost-effective cleanrooms save both time and money by reducing on-site labor, minimizing material waste, and shortening project timelines. Companies no longer need to invest in permanent structures that may become obsolete as their operations grow or change.

Additionally, modular designs often feature advanced HVAC systems, HEPA filtration, and ergonomic layouts that enhance operational efficiency. For instance, pharmaceutical cleanrooms benefit immensely from these features, as they maintain strict contamination control standards while allowing for rapid expansion or reconfiguration.

Podtech: Pioneering Modular Cleanroom Innovation

Among the leaders in the modular cleanroom solutions space, Podtech stands out for its innovative approach. Podtech specializes in delivering turnkey cleanroom modular systems that cater to a wide range of industries, from pharmaceuticals to high-tech manufacturing. Their solutions are not only flexible and cost-effective but also designed to meet global compliance standards.

Podtech’s modular approach allows businesses to scale their operations without the traditional headaches of cleanroom construction. Whether it’s adding new modules to increase capacity or relocate sections for process optimization, Podtech’s flexible cleanroom solutions make it possible to adapt quickly to changing industry demands.

Flexible Cleanroom Solutions for Modern Industries

Modern industries demand agility, and modular cleanrooms deliver just that. For example, in pharmaceutical manufacturing, production lines can change based on market demand. Modular cleanrooms enable rapid reconfiguration to accommodate new equipment or processes without disrupting existing operations.

In electronics and biotech sectors, contamination control is paramount. Cleanroom modular systems from Podtech provide precise environmental control while allowing for quick modifications, ensuring that companies can maintain high standards without sacrificing efficiency.

Moreover, these solutions are environmentally friendly. Modular cleanrooms minimize construction waste and often incorporate energy-efficient HVAC systems. This focus on sustainability aligns perfectly with modern corporate responsibility goals.

The Advantages of Modular Cleanroom Construction

Cleanroom construction has traditionally been a slow, expensive, and rigid process. Modular systems change the game. Here’s why:

- Speed: Off-site fabrication allows simultaneous site preparation and module construction, significantly reducing project timelines.

- Scalability: Expand or reconfigure your cleanroom as your business grows.

- Compliance: Prefabricated modules are designed to meet international standards like ISO and GMP, ensuring regulatory compliance.

- Cost savings: Lower labor and material costs, plus reduced downtime, make cost-effective cleanrooms an attractive option.

- Sustainability: Modular systems generate less waste and can incorporate energy-efficient technologies.

Interactive Elements: Making Cleanroom Solutions Immersive

Who said modular cleanrooms have to be boring? Many companies are now adding interactive features like modular workstation layouts, movable partitions, and even transparent walls for educational tours. Imagine a pharmaceutical cleanroom where students or visitors can safely observe processes through clear panels, learning while maintaining strict hygiene protocols. This interactivity not only enhances training but also boosts company engagement and branding.

Podtech’s Role in Shaping the Future

Podtech™ is quietly reshaping the world of cleanrooms. Rather than relying on slow, conventional construction, the company builds ready-to-deploy, modular environments that move as fast as industry demands. Each unit is crafted to be a living, adaptable system designed to respond to changes in technology, production, and regulation without the downtime of traditional setups.

These are precision-engineered ecosystems. From airflow to power distribution, fire safety to intelligent monitoring, every detail is integrated from the start, so industries can scale, pivot, or innovate at a moment’s notice. Small labs can grow into advanced manufacturing hubs without ever tearing down walls; complex operations can reconfigure instantly without disruption.

Podtech™’s approach flips the script on what a cleanroom can be. Instead of a fixed, static facility, it’s now a modular, intelligent, and endlessly flexible platform. For sectors like pharmaceuticals, biotech, electronics, and high-tech manufacturing, this means operational freedom, faster time-to-market, and the ability to experiment, expand, and evolve on their own terms. Podtech™ isn’t just delivering cleanrooms; it’s delivering the future of controlled environments.

Real-World Applications

Let’s take a closer look at how modular cleanroom solutions are used across industries:

- Pharmaceutical Cleanrooms: Podtech modules help maintain sterile conditions for drug manufacturing, research, and quality control.

- Biotechnology: Flexible modules allow biotech firms to scale experiments and production quickly.

- Electronics: Modular layouts accommodate rapid changes in production lines for sensitive electronic components.

- Food and Beverage: Contamination-free environments ensure product safety and regulatory compliance.

These examples highlight how flexible cleanroom solutions for modern industries are not just a trend but a necessity.

The Future of Modular Cleanrooms

The momentum behind the rise of modular cleanrooms shows no signs of slowing down. As industries demand faster, more adaptable, and cost-effective cleanrooms, the market will continue to evolve. Technologies like IoT integration, automated environmental monitoring, and AI-driven process optimization will make modular cleanrooms smarter, more efficient, and more sustainable than ever.

Building the Future with Modular Cleanrooms

The rise of modular cleanrooms is indeed a paradigm shift for industries that require clean, controlled environments. Modular cleanroom solutions offer speed, flexibility, and cost savings, making them indispensable for modern manufacturing, pharmaceuticals, biotechnology, and electronics.

With pioneers like Podtech leading the way, companies can now embrace flexible cleanroom solutions for modern industries without compromising on quality or compliance. Whether you’re expanding a pharmaceutical cleanroom, upgrading electronics production, or simply exploring cleanroom construction options, modular systems provide a future-ready solution.

So, the next time you think of cleanrooms, imagine a dynamic, adaptable, and modular environment where innovation meets efficiency. The world of modular cleanrooms is here, and it’s building the industries of tomorrow.

Ready to get started? Contact FTS today to explore modular cleanroom solutions tailored to your facility.