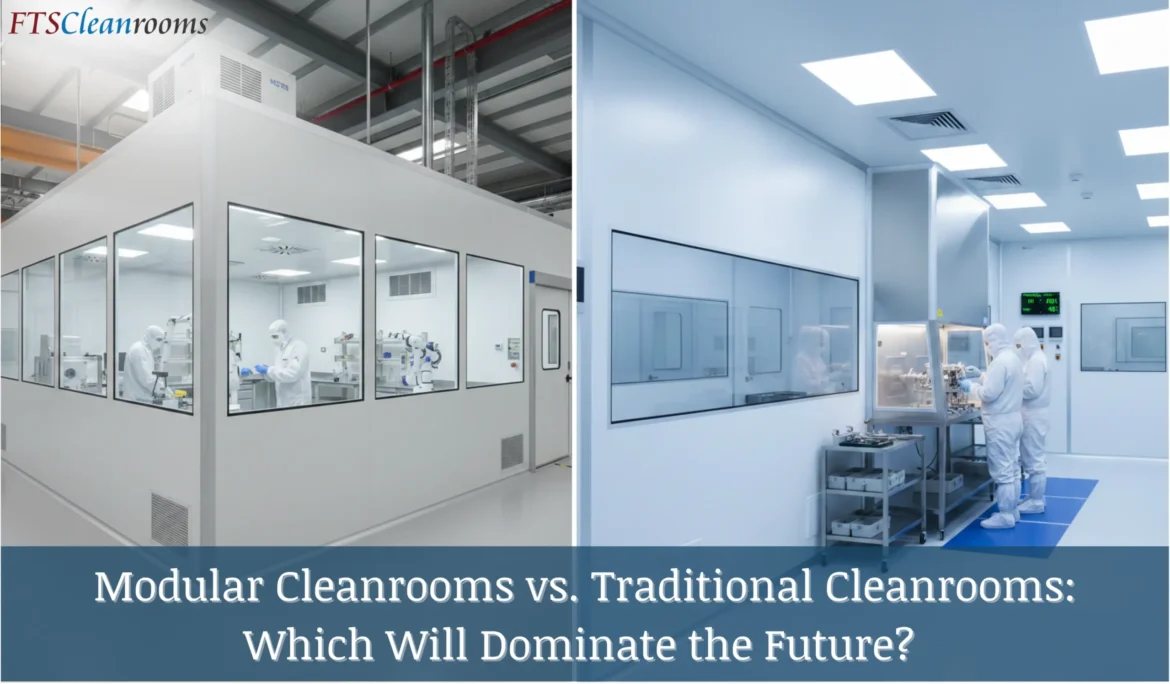

Modular Cleanrooms vs. Traditional Cleanrooms: Which Will Dominate the Future?

The future of high-tech manufacturing is being built right now, and it all starts with the cleanroom you choose.

Cleanrooms are controlled environments where temperature, humidity, and airborne particles are all strictly regulated, an essential requirement for industries such as pharmaceuticals, biotechnology, electronics, and semiconductors. As demand for precision-controlled environments grows, companies face a crucial decision: should they invest in a traditional (stick-built) cleanroom or adopt a modular cleanroom system? Both approaches have unique advantages and trade-offs, but which one is best suited to meet the future needs of high-tech industries?

In this article, we will explore the differences between modular vs. traditional cleanrooms, analyze their strengths and weaknesses, and examine which model, especially the rapidly advancing cleanrooms that are modular, is most likely to dominate the years to come.

Understanding the Two Models

Traditional Cleanrooms

A cleanroom that is traditionally built is constructed on-site using conventional building techniques. Walls, ceilings, HVAC systems, and utilities are built specifically for the facility, tailored to the exact requirements of the operation. These stick-built environments are permanent structures, fully integrated into the architecture of the building.

Advantages of Traditional Cleanrooms:

- Highly customizable layouts suitable for complex workflows

- Long-lasting and structurally permanent

- Complete integration with existing building systems

Drawbacks:

- Construction can take several months, delaying project timelines

- Higher costs due to labor-intensive processes and variable material expenses

- Disruption to ongoing operations during construction or renovation

Modular Cleanrooms

Modular cleanrooms are prefabricated cleanroom units that can be assembled quickly on-site. Panels, ceilings, and cleanroom HVAC systems are manufactured in factories and then installed like building blocks. Modular systems are designed to be flexible, reconfigurable, and, in some cases, relocatable.

Advantages of Modular Cleanrooms:

- Rapid installation, often taking weeks rather than months

- Flexible and scalable: rooms can be expanded, reconfigured, or relocated

- Cost-efficient due to standardized manufacturing and reduced labor

- Consistent quality through factory-controlled production

- Environmentally friendly, with reusable materials and energy-efficient systems

Challenges:

- Initial capital investment can still be significant, depending on system complexity

- Integration with existing utilities can be challenging

- Some perception of reduced permanence compared to traditional builds

Key Factors in the Debat

1. Time-to-Market

Modular cleanrooms have a clear advantage in speed. Modular cleanroom construction reduces on-site building time, allowing facilities to become operational faster. This is especially critical in the biotech and pharmaceutical industries.

Conventionally designed cleanrooms, while slower to construct, provide highly tailored designs for complex processes. Longer timelines, however, can delay product launches and operational efficiency.

2. Flexibility and Scalability

Flexibility is where modular cleanrooms shine because they can be expanded, reconfigured, or moved as business needs evolve.

Also, cleanrooms that are traditional are less adaptable. Modifying a stick-built cleanroom often requires extensive renovation, which is costly and disruptive.

3. Cost and Financial Predictability

Modular cleanroom benefits include predictable budgeting. Factory-built components reduce on-site uncertainties and minimize cost overruns.

Cleanrooms that are conventional involve more variables, labor, materials, and unexpected design changes, which can increase costs. Yet for large, permanent facilities, the durability and bespoke nature of traditional builds can justify the investment.

4. Regulatory Compliance and Quality Control

Both modern and older versions of cleanrooms can meet strict standards, including ISO 14644 cleanroom classifications, cGMP, and FDA regulations. Modular systems benefit from pre-engineered designs that simplify validation and compliance.

However, cleanrooms that are traditional offer full customization, which is advantageous for processes requiring unique or highly specialized setups.

5. Sustainability and Environmental Impact

Modern cleanrooms are generally more sustainable. Reusable panels, recyclable materials, and energy-efficient cleanroom HVAC systems reduce environmental impact.

Conventional cleanrooms may generate more construction waste and consume more energy for climate control over their lifetime.

6. Maintenance, Upgrades, and Lifecycle Cost

Modular systems simplify maintenance and upgrades. Panels and integrated systems allow easy servicing, and rooms can be reconfigured or expanded with minimal disruption.

Conventional cleanrooms, while durable, often require extensive work for upgrades, resulting in higher costs and operational downtime.

Modular vs Conventional Cleanroom: Pros and Cons

When evaluating modular vs conventional cleanroom pros and cons, it’s important to highlight practical differences. Modular cleanrooms offer faster installation, adaptability, and predictable costs, making them ideal for rapidly growing industries. They are flexible, scalable, and easier to maintain, with factory-controlled quality ensuring compliance with standards such as ISO 14644 cleanroom classifications.

Conventional cleanrooms, on the other hand, excel in fully customized layouts and structural permanence. They are often preferred for highly specialized processes where long-term durability and integration with existing building systems are critical. The main drawbacks include longer construction timelines, higher costs, and less flexibility for future upgrades or expansions.

In short, cleanrooms that are modular are suited for speed, flexibility, and cost efficiency, while cleanrooms that are conventional are preferred for highly specialized, permanent, and complex facilities. Understanding these distinctions is key for businesses weighing modular vs. traditional cleanrooms for their operations.

Market Trends and Future Outlook

Several trends indicate that cleanrooms that are modular are likely to dominate future cleanroom construction:

- Rapid Adoption: Increasingly used in biotech, pharmaceutical, and electronics industries due to speed, flexibility, and cost-efficiency.

- Scalability: Can be replicated across multiple sites or expanded in phases.

- Digital Integration: Equipped with smart sensors, real-time monitoring, and predictive maintenance systems.

- Sustainability: Reusable materials, lower waste, and energy-efficient cleanroom HVAC systems.

- Regulatory Confidence: Standardization and consistent manufacturing facilitate compliance.

Traditional cleanrooms will still serve:

- Large-scale, permanent facilities requiring extensive customization.

- Projects needing structural integration into existing buildings.

- Processes demanding high durability and permanence.

Strategic Recommendations

- Evaluate total lifecycle costs, including maintenance, energy use, and future upgrades.

- Prioritize flexibility, and cleanrooms that are modular provide adaptability unmatched by conventional cleanrooms.

- Leverage smart technologies for productivity and downtime reduction.

- Partner with experienced providers for smooth construction of cleanrooms that are modular and compliant.

- Consider sustainability goals and ESG objectives.

Conclusion

The debate between modular vs. traditional cleanrooms is evolving. While traditional cleanrooms remain valuable for specialized, permanent operations, modular cleanrooms are poised to dominate the future. Their speed, flexibility, cost predictability, sustainability, and integration with smart technologies make them ideal for industries facing rapid change and strict regulations.

The next decade will likely see a hybrid approach, combining the adaptability of cleanrooms that are modular with the customization of traditional builds, creating a cleanroom landscape tailored to modern industry needs. It’s time you partner with FTS Cleanrooms and discover the modular solution that fits your facility perfectly.